If you’re not sure about the grade, you’ll want to test it. 200 years ago, they’d make the rails with wood. Now that there are better and more standardized manufacturing methods, any track that’s only a couple of decades old is likely to be a 1084 or at least be very similar.Įarlier than that, though and it could be anyone’s guess. Obviously, not all railroad track will be exactly the same grade.

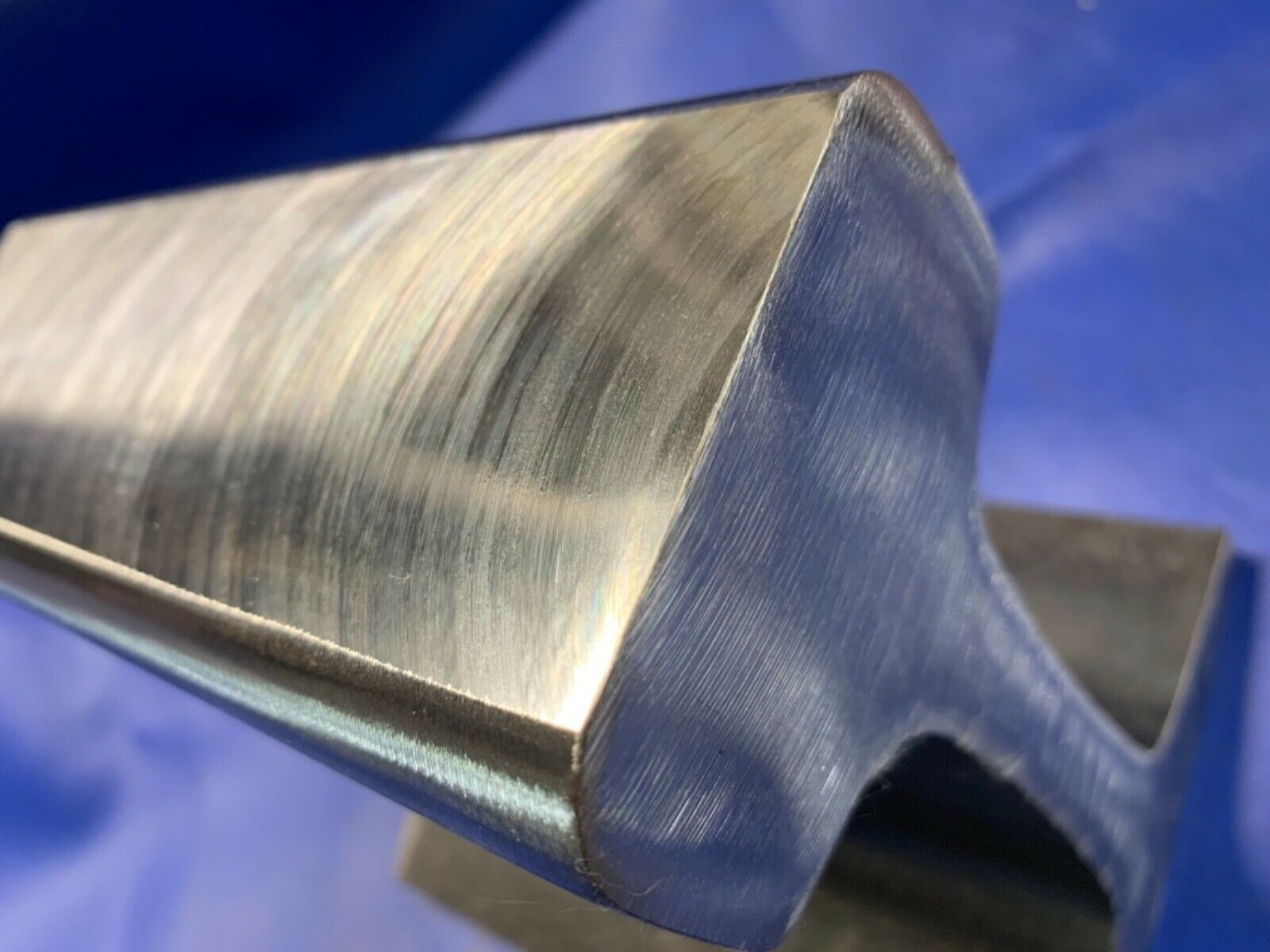

If it’s too cold then it’ll crack, if it’s too hot the carbon will burn out and you’ll have a miserable time with heat treating. For forging, keep it well between 15 F.If the track is annealed, you could even use an aggressive flap wheel on an angle grinder and remove a decent amount of material. Go with carbide inserts that have strong geometry for tough steels. Technically, you could do it, but it’ll be ugly and you’ll spend way too much time dressing your tools. Again, for machining: don’t bother with high speed steel cutters.Maybe call in a favor with a machinist buddy if you don’t have access. You need to heat it up to 1500 F and then slowly cool it to 1200 F at no faster than 50 F per hour.Annealing can be a little bit tricky unless you can a controlled oven. If you need to machine it, try annealing it first.If you do a half decent job with the torch, this zone will probably go in about half an inch max from your cut line. The HAZ is the part that is discolored (usually a straw or blue color). If you’re not sure how much of an area this is, do a little test cut.This will really mess up your heat treating – the metal will be soft on those ends. If you’re using heat to cut off a piece, make sure you leave lots of extra stock so that you can later remove the heat affected zone (HAZ).Use either a cutting torch (ideal) or a cutoff wheel (much slower) to cut off a length to work with.So here are some tips for cutting and working with railroad tracks: You’re not going to get too far with a hack saw. Tips for Working with Railroad Track Steel This means that if you cut off a foot of main line track, it will probably weigh over 40 lbs. For very small lines, like old ones for hand carts in mines, you might find it even smaller. Main lines will commonly be 130 pounds per yard, whereas smaller lines could get to around 70 pounds. Usually they’re designated by weight per yard. Here’s some more useful information about the size of the tracks: This is on the harder end of the “scrapyard metals” that are heat treatable – it will typically get harder than something like a leaf spring.They’re an excellent choice for most things that need heat treating.If this chart means nothing to you, here’s a quick explanation of what this means: If you’re into charts, here are some of the general properties of the steel: Characteristic A more ideal hardness is around 60-62 Rc, where the metal is sufficiently tough to resist cracking.Īt that hardness, the steel has a really good wear resistance. This will get rid of any “mushrooming”, wear or deformation of the metal.ġ084 steel can usually be heat treated up to 65 Rockwell C, but at that hardness it’s very brittle. That’s not to say that the rails are untouched for that amount of time – as the rails wear out, they can be “dressed” – a grinding process that will recondition the rounded top of the rails to restore its performance. Depending on the size of the trains and rate of use, a track could be expected to last anywhere from 5 to 100 years. Basically, it’s less likely that there would be surface cracks that would propagate over time.Īs you can imagine, trains are heavy and put an extraordinary amount of stress on anything below them. The deeper heat treatment allows the steel to have higher strength properties.

This is a requirement for good reason – it allows for deeper heat treatment.įor railroad tracks to perform well in the long term, there are two really important qualities that the steel needs to have: high wear resistance and resistance to fracturing. One of the noticeable features of this steel is the high manganese content.

0 kommentar(er)

0 kommentar(er)